In the realm of modern manufacturing, Computer Numerical Control (CNC) machining stands as a pivotal technology, enabling the precise and efficient fabrication of intricate parts and components. A key determinant of CNC machining’s success lies in the choice of materials used for fabrication. The versatility of CNC fabrication allows for the use of a wide array of materials, each with its unique characteristics and applications. In this comprehensive exploration, we delve into the diverse world of materials available for CNC machining, shedding light on their properties, advantages, and common applications. Whether you’re a seasoned engineer or a curious enthusiast, this article will serve as your guide to understanding the choices of materials available for CNC fabrication.

The Fundamental Role of Materials in CNC Fabrication

CNC fabrication, at its core, is the process of removing material from a workpiece to create a desired shape or product. The choice of material is paramount, as it directly impacts the precision, cost-effectiveness, and suitability of the manufacturing process. Selecting the right material ensures that the finished product meets the desired quality standards while optimizing production efficiency.

Plastics: Precision with Versatility

Plastics have gained prominence in CNC machining due to their versatility and cost-effectiveness. While not as robust as metals, plastics offer unique advantages:

- Acrylic: Acrylic, also known as Plexiglass, is a transparent plastic prized for its optical clarity. It is often used in the production of displays, signage, and medical devices.

- Nylon: Nylon’s exceptional durability and resistance to wear make it suitable for applications involving friction and stress. It is commonly employed in gears, bearings, and custom parts.

- Delrin (POM): Delrin, a type of polyoxymethylene, is known for its low friction properties and resistance to moisture. It is an excellent choice for precision parts like bushings and gears.

- Polyethylene: With its lightweight nature and chemical resistance, polyethylene is a popular choice for containers, tanks, and conveyor components.

Material Selection Factors in CNC Fabrication

Choosing the right material for CNC fabrication is a multifaceted decision influenced by several critical factors:

- Application Requirements

The first consideration should always be the specific requirements of the application. Is the part exposed to extreme temperatures, corrosive environments, or high stress? Identifying these needs helps in selecting materials with the requisite properties.

- Material Properties

Understanding the material’s properties, such as hardness, strength, thermal conductivity, and electrical conductivity, is crucial. It ensures that the chosen material aligns with the intended functionality of the part.

- Machinability

The ease with which a material can be machined is another pivotal factor. Some materials, like aluminum, are known for their excellent machinability, while others may require specialized tooling and expertise.

- Cost Considerations

Material cost can significantly impact the overall project budget. Balancing performance requirements with material costs is essential to maintain competitiveness.

- Tolerances and Surface Finish

Certain applications demand precise tolerances and impeccable surface finishes. Material selection should account for the CNC machine’s capability to achieve these specifications.

CNC Fabrication Applications for Various Materials

To gain a deeper appreciation for the choices available in CNC fabrication, let’s explore some real-world applications for the materials discussed:

- Aerospace Industry

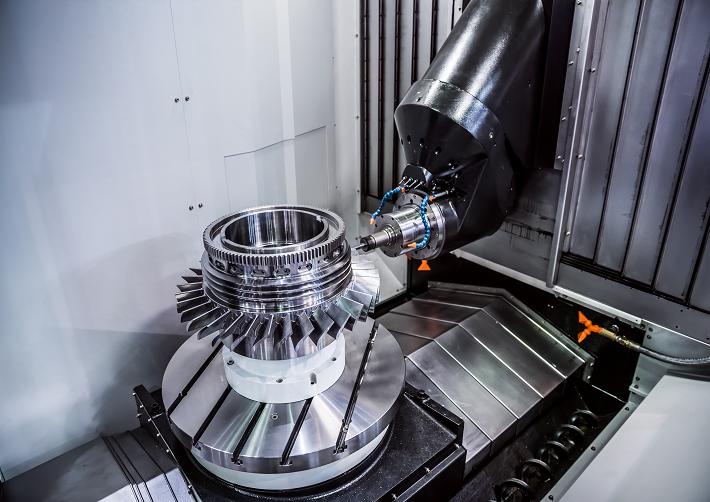

The aerospace sector demands materials that are lightweight, durable, and corrosion-resistant. CNC fabrication plays a vital role in crafting components such as aircraft structural parts and engine components. Aluminum, titanium, and various composites are extensively used due to their combination of strength and weight-saving properties.

- Medical Devices

In the medical industry, precision and biocompatibility are paramount. CNC machining is employed to create intricate surgical instruments, implants, and prosthetics. Materials like titanium and medical-grade stainless steel ensure both durability and biocompatibility.

- Electronics and Semiconductors

Electronics manufacturing requires materials with excellent electrical properties and thermal management capabilities. Aluminum, copper, and specialized plastics are used to fabricate heat sinks, enclosures, and connectors.

- Automotive Sector

Automotive parts must withstand diverse conditions, from extreme temperatures to mechanical stress. Steel and aluminum are commonly used for engine components, chassis, and various automotive parts due to their strength and lightweight properties.

- Consumer Goods

In the world of consumer goods, aesthetics often plays a crucial role. Acrylic and various plastics are CNC machined to create visually appealing products like smartphone cases, displays, and decorative items.