Searching for ways to enhance the performance and reliability of components in Denver’s automotive industry? Look no further than the remarkable material known as INVAR 36. In the world of automobiles, precision, stability, and durability are paramount, and INVAR 36 excels in delivering these qualities. In this article, we will delve into the top five benefits of using INVAR 36 in Denver’s automotive industry.

Understanding INVAR 36: The Ideal Material for Automotive Applications

Before we explore the benefits of INVAR 36 in the automotive industry, let’s first understand what makes this material so unique and valuable. INVAR 36 is a specialized nickel-iron alloy known for its low coefficient of thermal expansion. This property means that it experiences minimal dimensional changes as temperatures fluctuate, making it an ideal choice for applications where temperature stability is critical.

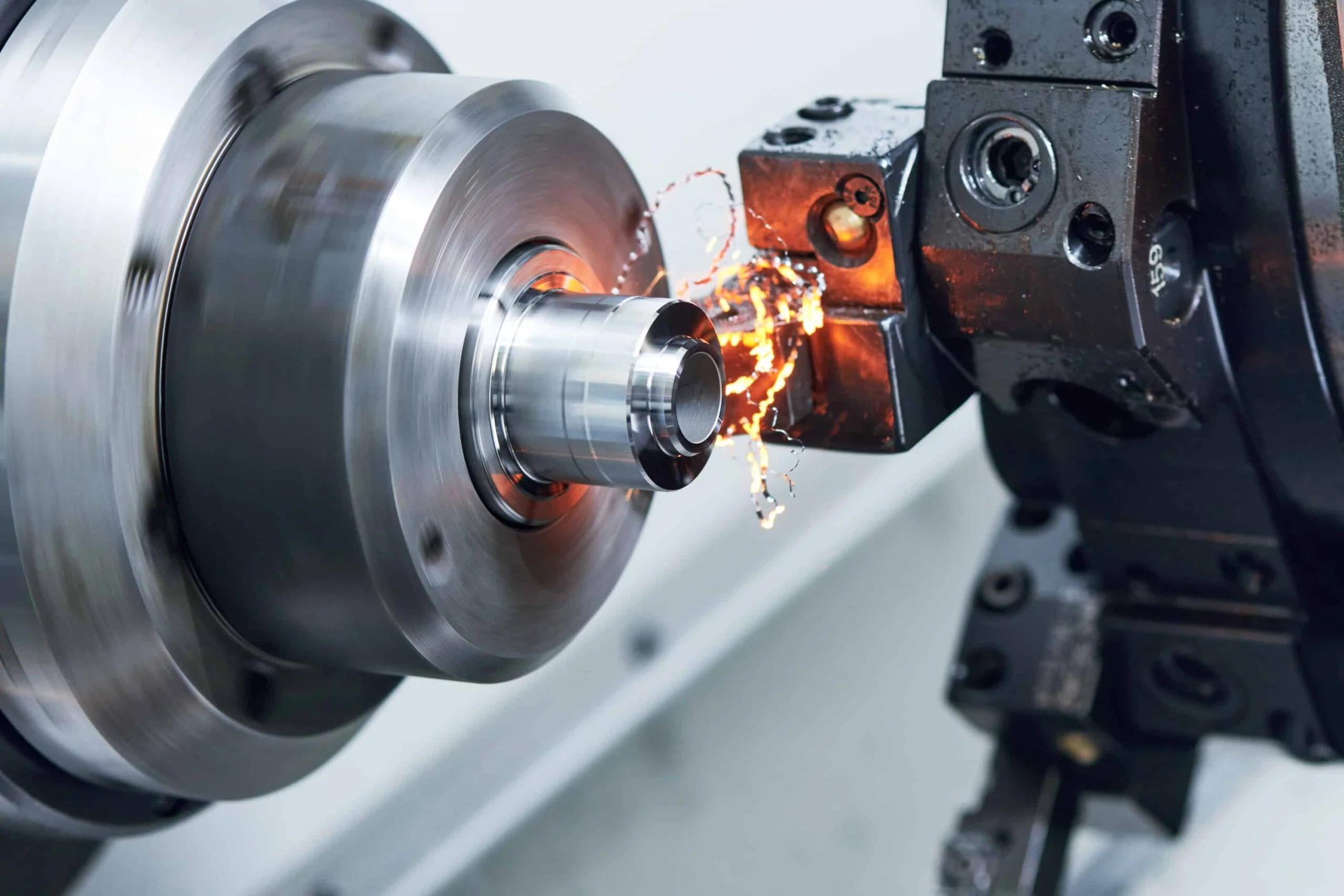

1. Precision in Manufacturing

Precision is the bedrock of the automotive industry, where even the slightest deviation from specifications can lead to performance issues and safety concerns. INVAR 36’s low thermal expansion coefficient ensures that parts and components maintain their precise dimensions, even when subjected to temperature variations. This quality makes INVAR 36 an excellent choice for manufacturing precision components such as engine parts, transmission components, and sensor housings.

2. Stability in Extreme Temperatures

Denver experiences a wide range of temperatures throughout the year, from scorching summers to frigid winters. Components in automobiles must perform reliably across these extreme conditions. INVAR 36’s ability to resist dimensional changes in response to temperature fluctuations ensures that automotive parts made from this alloy remain stable and continue to function optimally, regardless of the weather.

3. Reduction in Vibration and Noise

Vibrations and noise can be a significant concern in automobiles. They not only affect ride comfort but can also indicate underlying issues with the vehicle. INVAR 36’s stability and resistance to thermal expansion can help reduce vibrations and noise by ensuring that components remain securely in place and maintain their intended shapes. This contributes to a quieter and more comfortable driving experience.

4. Corrosion Resistance

Automobiles are exposed to a wide range of environmental conditions, including moisture and road salt during the winter months. INVAR 36’s corrosion-resistant properties make it an excellent choice for components that are prone to exposure. This corrosion resistance ensures the longevity of automotive parts, reducing maintenance and replacement costs.

5. Enhanced Fuel Efficiency

Fuel efficiency is a top priority for both consumers and automakers. INVAR 36’s stability and precision contribute to improved fuel efficiency by ensuring that critical components, such as engine parts and exhaust systems, operate at their optimal levels. The reduced need for adjustments and replacements also leads to cost savings and sustainability benefits.

Why Choose Preece Machining and Assembly for INVAR 36 in Denver’s Automotive Industry?

Now that we’ve explored the advantages of using INVAR 36 in Denver’s automotive industry, the next crucial step is finding a reliable supplier. For all your INVAR 36 needs, look no further than Preece Machining and Assembly. Preece Machining and Assembly has a long history of supplying high-quality INVAR 36 to various industries, including automotive. With their extensive expertise, they understand the unique requirements of the automotive sector and can provide tailored solutions to meet your specific needs.