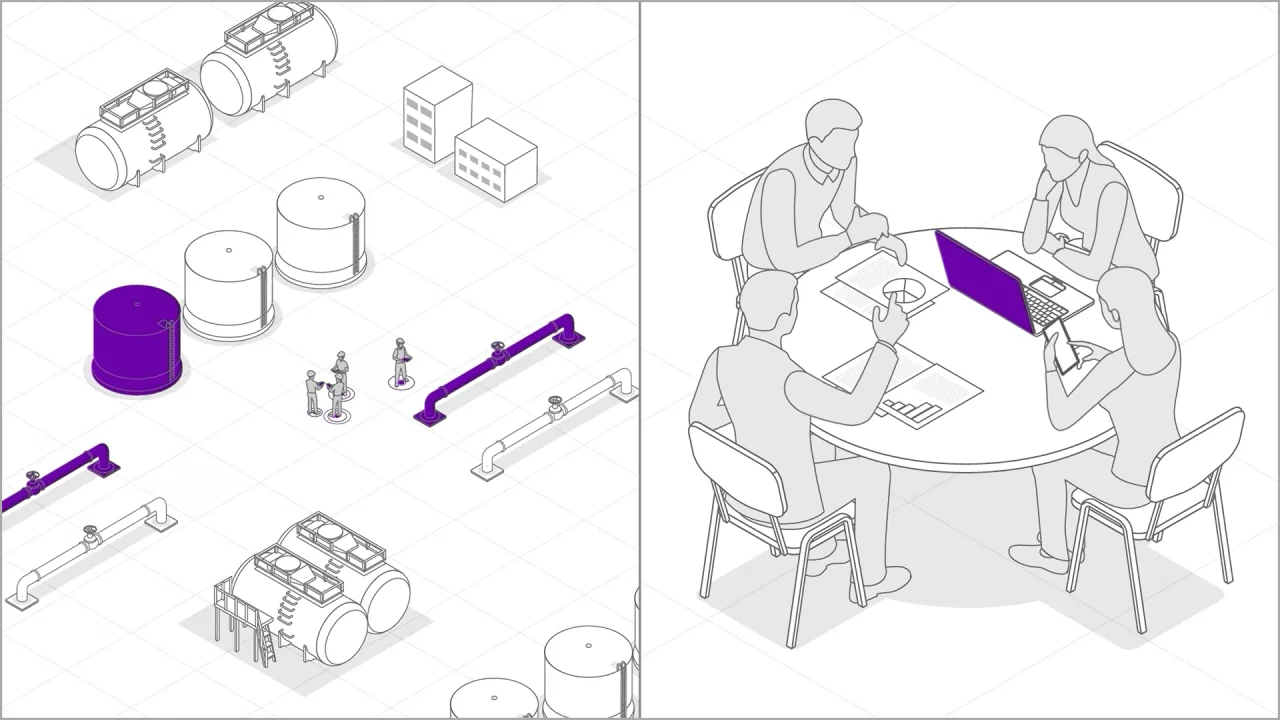

In the ever-evolving oil and gas sector, companies always look to enhance their operations, increase efficiency, and minimize risks. One such technological advancement that has emerged as a game-changer in this industry is Pipeline Connectivity Model Software. This sophisticated software is not only transforming the way companies manage their pipelines but also making a significant impact on various modern industries. Here is the role of Pipeline Connectivity Model Software in the oil and gas sector and its broader implications for modern industries.

Efficient Resource Management

In the oil and gas sector, efficient resource management is crucial for optimizing production and minimizing downtime. Software like Pipeline Unity plot software gives companies a real-time view of their pipeline infrastructure. It enables them to monitor the flow of resources, detect leaks or anomalies, and make quick decisions to address issues promptly. This real-time data access empowers companies to reduce wastage and enhance resource utilization, resulting in substantial cost savings.

Enhanced Safety Measures

Safety is supreme in the oil and gas industry, where any mishap can have devastating consequences. Pipeline Connectivity Model Software plays a vital role in ensuring safety by continuously monitoring the integrity of pipelines. It can detect potential threats, such as corrosion or structural weaknesses, and alert operators before these issues escalate into emergencies. By proactively addressing safety concerns, companies can prevent accidents, protect the environment, and safeguard their reputation.

Streamlined Operations

Pipeline Connectivity Model Software streamlines operations by automating tasks that were previously time-consuming and prone to human error. This includes data collection, analysis, and reporting. With automation, companies can reduce the risk of data inaccuracies and free up their workforce to focus on more critical tasks. This efficiency translates into improved productivity and faster decision-making, invaluable in a fast-paced industry like oil and gas.

Environmental Impact Reduction

Modern industries are under increasing pressure to reduce their environmental footprint. Pipeline Connectivity Model Software aids in achieving this goal by helping companies minimize leaks and emissions. The software contributes to environmental conservation efforts by promptly identifying and addressing issues. This is good for the planet and aligns with the sustainability goals that many companies are pursuing today.

Expansion into Other Industries

The benefits of Pipeline Connectivity Model Software are not limited to the oil and gas sector alone. Its success has prompted companies in various other industries to explore its potential. For example, water utilities use similar software to manage their vast network of pipelines, ensuring the efficient distribution of clean water. The transportation industry also adopts this technology to monitor and maintain pipelines carrying fuels and other critical resources.

Predictive Maintenance

Pipeline Connectivity Model Software goes beyond mere monitoring; it leverages cutting-edge analytics and machine learning algorithms to enable predictive maintenance. The software can predict when maintenance or repairs will be needed by analyzing historical data and real-time information. This proactive approach minimizes downtime and reduces the chances of costly breakdowns, ensuring uninterrupted operations for companies in the oil and gas sector and beyond.

Regulatory Compliance

Compliance with industry regulations is constantly challenging for companies, especially in highly regulated sectors like oil and gas. Pipeline Connectivity Model Software plays a crucial role in helping businesses adhere to these regulations. It generates detailed reports and documentation demonstrating safety, environmental, and operational standards compliance. This ensures legal compliance and enhances a company’s reputation as a responsible and trustworthy player in the industry.

Remote Monitoring and Control

Modern industries often involve complex and extensive infrastructure that spans vast geographical areas. Pipeline Connectivity Model Software enables remote monitoring and control of pipelines and related facilities. This means that operators can manage their assets from a central location, reducing the need for physical presence at remote sites. This remote capability not only improves operational efficiency but also enhances safety by minimizing the exposure of personnel to potentially hazardous environments.

Conclusion

Pipeline Connectivity Model Software has undoubtedly revolutionized the way companies in the oil and gas sector operate. Its ability to enhance resource management, improve safety measures, streamline operations, and reduce environmental impact has made it an indispensable tool in the modern industrial landscape. Furthermore, its successful implementation in the oil and gas sector has inspired other industries to explore its potential benefits.

As we look ahead, it’s evident that the role of Pipeline Connectivity Model Software will continue to expand, shaping the future of modern industries by providing them with the tools they need to operate efficiently, sustainably, and safely.