A Comprehensive Guide to Plastic Mold Manufacturing in China

Mold manufacturing for plastic is an industry of major importance in China. Being the biggest producer of plastic-based products, China has developed extensive capabilities in the design of plastic molds tools, tooling, machining injection molding, and various other mold-making processes made of plastic.

In this post will provide an extensive review of the plastic mold industry in China How it functions and the various types of molds, the materials used application, top providers of molds, prices and advice on finding high-quality molds made of plastic from China.

What is a Plastic Mold?

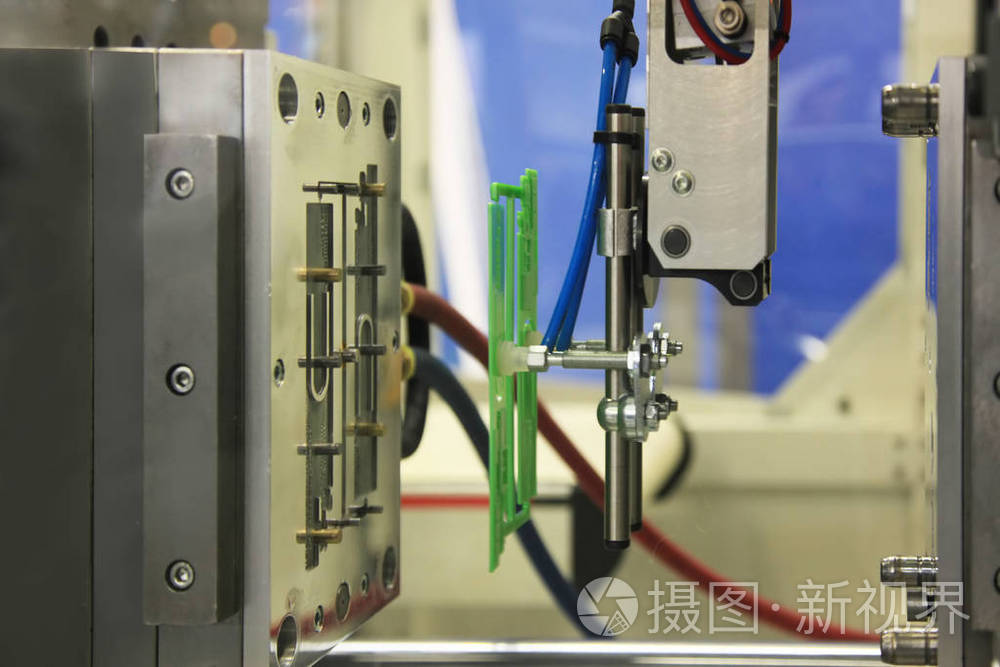

Engineers design plastic molds as custom tools to shape molten plastic into desired forms using injection molding or other plastic molding processes. Plastic molds consist of two halves – the core side and the cavity side. When closed under pressure, the mold cavity gets injected with plastic material which takes shape inside it.

Manufacturers construct automotive bumper mould using aluminum or tool steel. The choice of material depends on cost considerations, strength needs, hardness and the expected production run size. Steel molds are more durable for high volume production while aluminum molds are cheaper but cannot withstand high pressures.

Engineers create the mold cavity based on the desired specifications and shape of the final plastic part. Complex 3D shapes require advanced CNC machining capabilities. The mold design also includes dedicated runners and gates through which the molten plastic flows into the cavity.

Types of Plastic Molds

Plastic molds are classified into different types based on the molding process used:

Injection Molds

Engineers use injection molds for injection molding, the most common plastic molding process. Injection molds are complex, high-precision tools built to withstand high temperatures and pressures. Quality factors include uniform wall thickness, proper draft angles, and desired surface finishes.

Blow Molds

Blow molds shape hot plastic material into hollow products like bottles through blow molding. They consist of two halves designed to withstand high internal pressure.

Rotational Molds

Rotational molding uses rotational molds to create seamless, hollow, stress-free plastic components. These molds have two halves rotated and heated during the molding process.

Compression and Transfer Molds

Compression molding and transfer molding employ simple, two-piece molds with minimal moving parts. The straightforward designs suit these niche molding processes.

Thermoform Molds

For thermoforming, molds made of wood, epoxy or aluminum provide the shape templates.

Plastic Mold Manufacturing Process in China

Manufacturing high-quality plastic molds requires specialized skills, equipment, and expertise. The typical plastic mold making process in China involves:

- Engineers create 3D CAD models and detailed technical drawings for the mold tooling. They conduct advanced engineering analysis using Moldflow and other software.

- Technicians convert the design data into precise CNC toolpaths to machine the mold components.

- Machinists cut and machine blocks of tool steel or aluminum on CNC machining centers. EDM creates complex mold cavities.

- Workers polish mold surfaces to specified finish standards using automated processes. Texturing adds custom surface effects.

- Staff assemble the finished mold halves and components. Testing validates mold performance before starting production.

- Additional finishing steps include heat treatment, plating, laser etching etc.

The top plastic mold makers in China can produce molds with exceptional surface quality, dimensional accuracy and consistency. Automation allows high production efficiency and cost savings compared to other countries.

Plastic Mold Design Considerations

Mold designers must have a thorough understanding of the plastic material, mold methods and techniques for mold making. Key design considerations include:

- Plastic Material Properties flow characteristics and shrinkage. Also, thermal expansion, and other effects.

- Part Design Part Design – uniform wall thickness Draft angles, the fillets and radius, and ribs for added the strength. Beware of warping and sinks.

- Runner as well as Gate Design – For balanced flow and a perfect mold filling patterns.

- Cooling Channels – Useful arrangement of the cooling channel to decrease cycles.

- Cavity Polishing Surface finish requirements and texture.

- Mechanical Functions – Components for expulsion, sliding cores as well as unscrewing.

- Standard Components – Utilizing standardized base molds, mould inserts, and hot runners.

- Automation – Designing for automated production as well as the speed of production.

A well-designed mold minimizes the risk of defects like flashes, short shots warpage and increases part performance and cost.

Plastic Mold Materials Used in China

China commonly utilizes the following plastic mold materials:

- P20 Tool Steel provides versatility, strength and cost-effectiveness. Manufacturers heat treat it to achieve 60 HRC hardness.

- 718 Steel offers higher hardness between 50-55 HRC along with excellent wear resistance and longevity. It is used for large production runs.

- S136 Steel achieves 56 HRC hardness and polishability. It is suitable for small, precision plastic molds.

- Aluminum Alloys are softer but cheaper materials for prototype molds and low volume production runs.

- Beryllium Copper is a specialty alloy with high thermal conductivity used to create conformal cooling channels.

- Stainless Steel provides corrosion resistance. It is used for molds that inject corrosive plastics.

The choice of material depends on the production run size, required mold strength and the plastic material being used. Pre-hardened tool steels allow faster machining while custom heat treating can optimize hardness.

Plastic Mold Industry in China

China is the top maker of plastic molds, with the market estimated to be around $25 billion. Its Pearl River Delta region, specifically Guangdong province is at the core of manufacturing plastic molds in China.

Many Chinese businesses offer molds made of plastic for design tools, finishing, and assembly. It ranges from small factories to larger enterprises equipped with modern equipment and capabilities.

The advantages of the plastic mold manufacturing industry in China are:

- Low costs Costs for labor construction, raw materials, and infrastructure cost are less than in Western regions. Pricing is highly competitive.

- Production Capacity Huge capacity backed by hundreds of shops and a skilled workers for large-scale production.

- Molding Materials Available the tool steel as well as aluminum alloys, and other the standard parts.

- Equipment Large investment in CNC machines that are advanced EDM, LASER technology for manufacturing automation, and other technologies.

- Specialization Businesses devoted to certain mold types, plastics, industries, as well as secondary processing.

- Supply Chain A comprehensive supply chain of mold components, parts heating treatment, plating etc.

Quality control, however, and protection of intellectual property are important issues to be on the lookout to when buying molds in China.

Applications of Plastic Molds

Molds made of plastic are utilized to make a variety of plastic items across all sector:

- Automotive – Both exterior and interior parts such as bumpers, panels switches, lights, dashboards.

- Consumer Goods: Appliances, electronic furniture, furnishings homewares, sporting equipment, and household items.

- Diagnostic Medical devices Containers, disposable syringes and disposable containers.

- Packaging – Caps, bottles boxes, bins, containers and containers for all kinds of items.

- Toys & Games – Action models, building blocks and playsets that are molded with bright hues.

- Industrial – Gears, Rollers tools, housings for tooling, labels and signage. Machine components.

- Agriculture – Trays and pots Watering tools, Trays.

and numerous others. The latest mold designs and manufacturing technology allows for the production of mass quantities of low-cost practical plastic items which are commonplace in contemporary daily life.

How do you find the best Quality plastic molds in China

Here are some tips to source high-quality plastic molds from China:

- Definition of requirements The specification should include the plastic material annually, quantities, precise demands, finishes on surfaces secondary processing as well as test expectations.

- Assess the quality of suppliers Review the credentials of their clients, reviews from customers internal capabilities, certificates, and previous experience on similar project. Find references.

- Request for Prototypes – Try out potential suppliers ‘ prototypes by placing an order prior to implementing full-production tools.

- Engineering Review – Review the mold’s drawings with your designer prior to machining, in order to verify conformance.

- Production Monitoring Schedule tests and inspections in the factory while molds are being made.

- IP Security Authorize NDAs as well as owner’s agreements for mold. Beware of sending complete 3D CAD-related data.

- Validation Tests – Make sure to thoroughly test the sample following tooling’s completion prior to approving complete mold orders.

Source your supplies from reputable, established firms such as JEVEN Plastics with demonstrated design engineering expertise and capability for management is highly recommended to ensure always high quality result.

Costs of plastic molds made in China

The costs of molds for plastic made in China includes:

- Mold Design Costs from $1,000 up to $5,000, based on the complexity.

- tooling costs from $2,000 to $20,000.and up, depending on the dimensions materials, amount of holes, finishes on the surface and their complexity.

- Secondary Methods Between $500-$2,000 for plating, heat treatment or laser etching.

- Production Piece Costs Vary based upon dimensions, material manufacturing processes, post-molding techniques as well as order volume. Expect $0.50 – $5 per piece.

- Shipping & Logistics – Duty, freight and local delivery cost.

The mold tooling expense is typically 15% to 25% of the life-time cost of a plastic product. The delivery timeframes that have been delayed typically attract more expensive prices between 20 and 50 percentage. Making mold prototypes in cheaper materials could result in considerable savings at the start.

Conclusion

China provides a full environment for low-cost plastic mold production. Utilizing the best designs, engineering and the right quality control procedures and supply chain management Chinese moldmakers can provide quality, high-precision production molds that can be used for complicated plastic items.

Through leveraging China’s superiority in the field of tooling, the automation of processes and expert expertise, and reducing risks related to IP and quality Businesses from all over the world are able to benefit from purchasing plastic molds from China to meet their production needs.