In the modern industrial realm, the dynamics of surviving in the industry sector depend on chasing efficiency. Organizations working on energy generation, manufacturing, and many more look for feasible solutions to streamline operations, reduce downtime, and make data-driven decisions. Constant scientific research and innovation have produced systems capable of infusing automation into the preset operational infrastructure of industries. Enter Supervisory Control and Data Acquisition (SCADA) systems; the unheralded champions silently revolutionizing industrial processes behind the scenes. A scada control panel or system improves factory efficiency and precision by tenfold. This results in considerable revenue generation. This article is dedicated to readers to learn in detail about Scada systems and their importance in industries.

Deciphering SCADA: An Overview

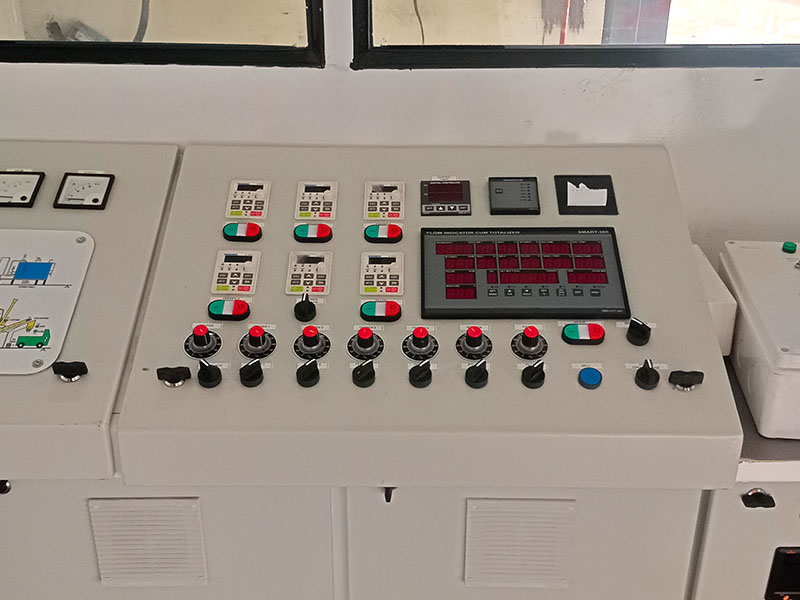

SCADA is an acronym for Supervisory Control and Data Acquisition. It encompasses a sophisticated ecosystem of software and hardware components. Scada control panel is vital in streamlining industrial processes. Its multifaceted functionalities include:

- Local and remote control of industrial processes.

- Real-time monitoring, collection, and analysis of data.

- Direct interaction with equipment via Human-Machine Interface (HMI) software.

- Comprehensive event logging for audit and analysis purposes.

The Backbone of Industry

The scada control panel or systems work as the backbone for various commercial sectors. These sectors include energy, transportation, manufacturing, and many more. These systems play an important role in maintaining operational efficiency. Scada systems help in data-driven decision-making, address functional anomalies, and reduce downtime.

The Wide Reach of SCADA: Who Benefits?

Several industries spread over public sectors and private utilize a scada control panel or systems. These industrial entities use SCADA systems to bolster efficiency, control, and communication within their operations. The use of SCADS systems has extended to various industrial belts, such as:

- Energy production and distribution

- Food and beverage processing

- Oil and gas exploration and refining

- Water treatment and wastewater management

- Transportation infrastructure management

- Recycling and waste management

- And numerous others

Illustrating Success: Insights from Case Studies

A plethora of case studies underscores the tangible benefits derived from modern SCADA solutions like Ignition. From substantial cost savings to heightened productivity and reliability, well-implemented SCADA systems serve as invaluable assets in navigating the complexities of contemporary industrial landscapes.

Embracing Progress: The Evolution of SCADA Systems

A modern scada control panel or systems epitomize a paradigm shift in industrial automation. With the capability to access real-time data from any location worldwide, these systems empower stakeholders to make informed decisions with unprecedented precision and agility.

Streamlining Design: The Role of Rapid Application Development (RAD)

Contemporary SCADA designer applications boast Rapid Application Development (RAD) functionalities, enabling users to craft applications effortlessly, irrespective of their software development proficiency. This democratization of design fosters innovation and flexibility within industrial environments.

Integration with IT Standards: Elevating Efficiency and Security

The incorporation of modern IT standards such as SQL and web-based applications has revolutionized SCADA software architecture. Leveraging the prowess of SQL databases, SCADA systems seamlessly integrate with existing Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms, facilitating seamless data flow across organizational silos.

Unveiling Insights: Harnessing the Power of Historical Data

The scada control panel or systems equipped with SQL databases offer unparalleled advantages, including simplified data analysis through trend analysis. The ability to log historical data enables organizations to glean invaluable insights into their operations, paving the way for continuous improvement and optimization.

Pioneering the Future: A Data-Centric Frontier

As industries undergo digital transformation, SCADA systems or a scada control panel will continue to play a pivotal role in shaping the future of industrial automation. By harnessing real-time data and advanced analytics, organizations can navigate the intricacies of the modern industrial landscape with confidence and precision.

Summing Up

In an era characterized by relentless technological advancement and fierce competition, SCADA systems emerge as catalysts for efficiency and innovation. From optimizing production processes to ensuring regulatory compliance, these systems empower organizations to thrive in an increasingly interconnected world. As industries embrace the transformative potential of SCADA technology, the horizons of efficiency, productivity, and growth expand exponentially. The scada control panel has introduced industrial automation as well as exponential growth in efficiency, productivity, and unrestricted communication between operations. Several companies and businesses spread over various sectors use SCADA systems to streamline their industrial process and relocate their manpower to more complex matters. This helps them achieve a workable ecosystem that can guarantee a return on investment. Management can make data-driven decisions due to the access to historical data that can influence human decisions. The objective of this article is to provide a clear understanding of SCADA systems along with their importance in industrial sectors.