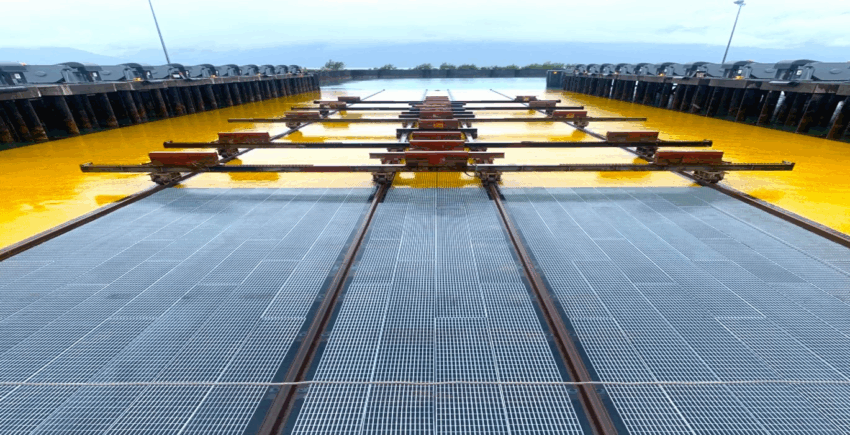

In the manufacturing industry, choosing the right materials for construction and production is essential. Pultruded Fiber Reinforced Polymer (FRP) grating has become an important choice for many manufacturers due to its strength, durability, and safety features.

The advantages of pultruded FRP grating make it ideal for use in manufacturing facilities and various other industrial applications. In this article, we will explore five key advantages of pultruded FRP grating in the manufacturing sector.

1. Strength and Durability

One of the primary benefits of pultruded FRP grating is its impressive strength and durability. This material is known for its ability to withstand heavy loads, making it perfect for environments where high performance is required.

Unlike traditional materials like steel, FRP grating does not corrode, rust, or weaken when exposed to chemicals or moisture. This makes it a long-lasting solution in manufacturing settings, where tough conditions are common.

2. Lightweight and Easy to Handle

Pultruded FRP grating is much lighter than many other materials used in manufacturing, such as steel or concrete. This makes it easier to handle, transport, and install, which can save both time and money during the construction process.

Workers can easily move and install FRP grating without needing heavy equipment, reducing the risk of injuries on site. The lightweight nature of this material also makes it easier to work with in terms of maintenance and replacements, as there is less strain on structures and support systems.

3. Non-Conductive Properties

Another significant advantage of pultruded FRP grating is its non-conductive nature. This property is particularly important in manufacturing environments that involve electrical components or hazardous materials.

FRP grating prevents the risk of electrical shocks and short circuits, providing a safer environment for workers. It also ensures that the grating will not conduct heat, which can be beneficial in temperature-sensitive manufacturing areas.

4. Corrosion Resistance

In many manufacturing processes, materials are exposed to harsh chemicals, oils, and other corrosive substances. Steel and other metals can corrode over time when exposed to these materials, leading to the need for frequent replacements.

Pultruded FRP grating, however, is highly resistant to corrosion. It can withstand prolonged exposure to chemicals, making it an excellent choice for industries such as chemical processing, food production, and wastewater treatment.

5. Customization and Versatility

Pultruded FRP grating offers a high degree of customization, allowing manufacturers to create grating that meets their specific needs. The material can be molded into various shapes, sizes, and designs to fit different applications.

Whether it is for a walkable surface, drainage cover, or a structural support, pultruded FRP grating can be tailored to suit the unique requirements of any manufacturing environment. This versatility allows manufacturers to implement the material in a wide range of applications.

Conclusion

Pultruded FRP grating offers many advantages for the manufacturing industry, including strength, durability, and resistance to corrosion. Its lightweight and non-conductive properties make it a safer and more manageable option compared to traditional materials.

Additionally, the ability to customize FRP grating means that manufacturers can use it in a variety of applications. Overall, pultruded FRP grating is a valuable material for manufacturing environments, offering a cost-effective and long-lasting solution to meet the demands of modern industries.